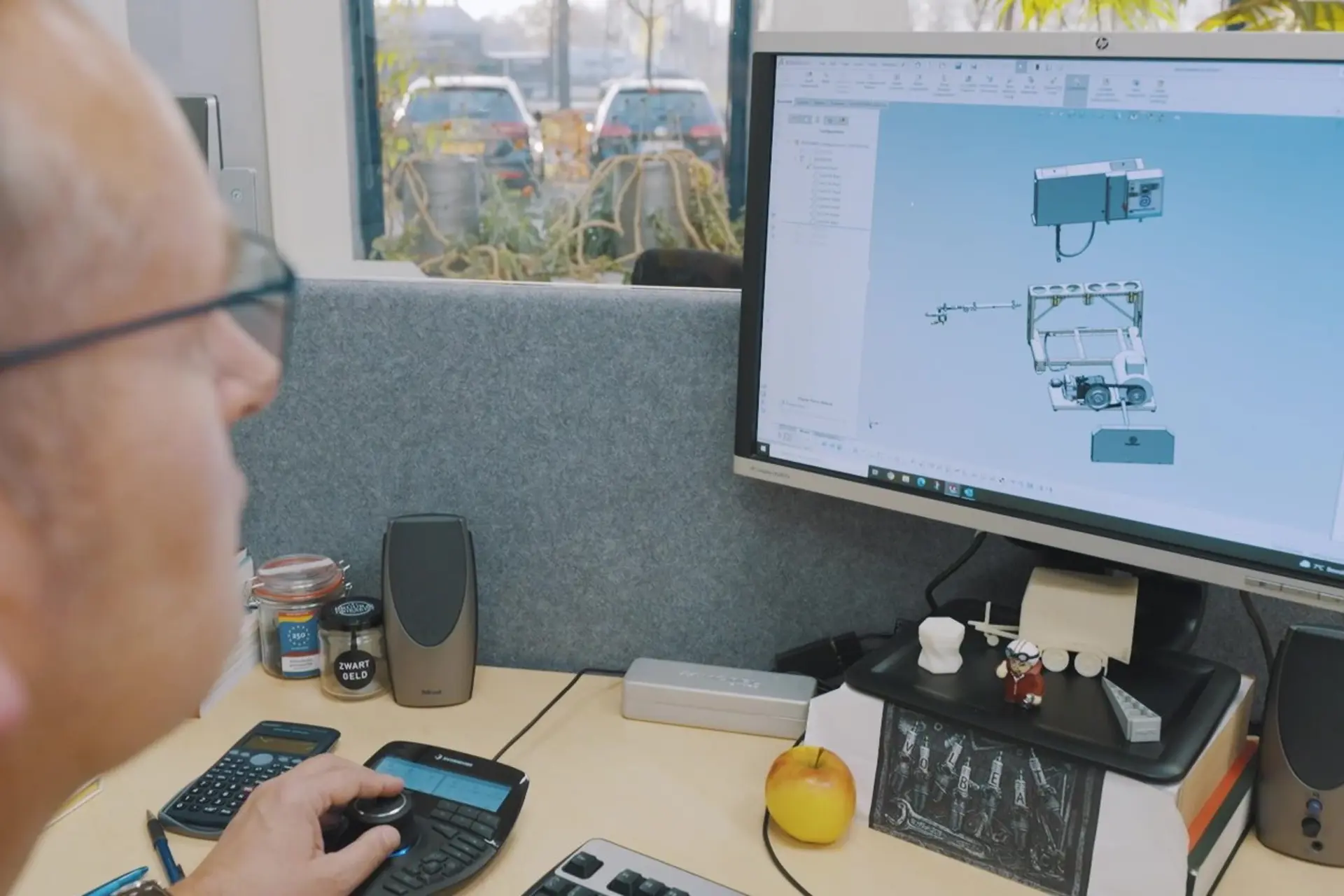

Develops, designs and assembles

We develop, design and assemble machines for a variety of applications based on hot and cold water high-pressure technology. Waterkracht is also an importer of state-of-the-art high-pressure pumps, high-pressure cleaning machines and accessories.